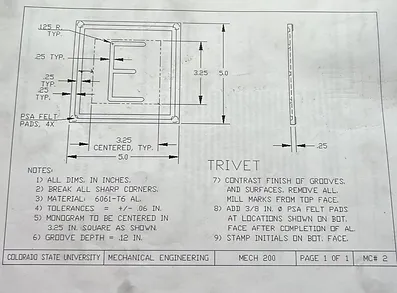

The Trivet Project

This was the final of three projects that were manufactured in the CSU-EMEC!

About the Trivet

This project was by far my favorite out of the three for MECH200. It was by far the quickest and easiest, but its goal was to highlight creativity.

Engineering specifications by Dr. Steven "Doc" Schaefer.

Process Summary

The main goal of this part was to learn about G code and how to work the CNC machines because they are the industry standard in current times.

Students were given a plain aluminum plate to work with. The first goal was to ensure the correct 5"x5" frame, which was done on the vertical mill.

Next the students used MasterCAD© to design the imprint on the plate. I chose to make a couple mountains and have a moon sitting in between them.

The CAD file was then converted into G-code, and then put in the CNC mill to make the design come to life.

Finally...

The finish I decided to put on this part made it look super cool. I put it in the tumbler for about a day and took it out to let it go in the CNC mill, so it has a rustic look but also clean since the decoration was added after being tumbled.

I also stamped my initials on the bottom of the piece. It currently is at my home in Alaska. I gave it to my stepmom and she uses it every night at the dinner table!

**The CSU-EMEC is an amazing opportunity for Engineering students. We are allowed to utilize it anytime after completion of MECH200, so it is often used for senior design projects or certain clubs like the Rocket Team. I am so grateful I got to experience hands on manufacturing. It was fun to go home that summer and show my dad that I already knew everything he wanted to teach me.**