The Screwdriver Project

This was the second of three projects that were manufactured in the CSU-EMEC!

About the Screwdriver

The screwdriver project was another part of MECH200. It was assigned after the completion of the clock. It used many different machining processes that were not included in the clock project!

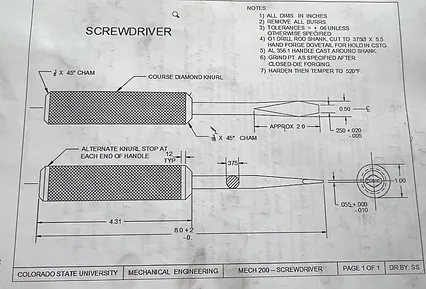

The engineering drawing specifications designed by Dr. Steven "Doc" Shaeffer.

Process Summary

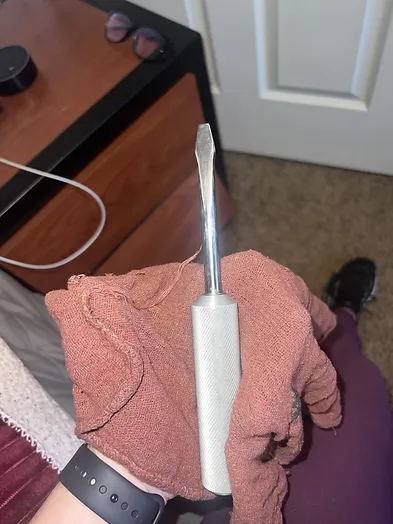

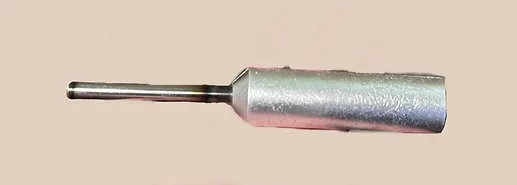

The screwdriver was a super fun part to make. We were given the base as shown in the figure below. The manufacturing processes utilized in this part included:

In the manual lathe, we finished off the base and drilled a small pilot hole, and then inserted it into the knurling attachment in the lathe. Knurling was how the diamond patter on the handle was acheived.

Then we had to forge the head by heating it up and using a drop force to shape it further into the screwdriver shape. We then oil quenched it for heat treatment.

The last step was to spend hours grinding away the unnecessary metal so it could look pretty.

Finally...

This part was super fun to make. The forging process was difficult because I had to make sure it was hot enough to put into the drop forge, and then still hot enough to heat treat.

I also really enjoyed getting to grind all the metal away and then sand it to make it look exactly how I wanted it to. Currently it is sitting in my dad's tools, and I have heard that he uses it from time to time.