The Metal Clock Project

This was the first of three projects that were manufactured in the CSU-EMEC!

About the Clock

The metal clock was the first project in MECH200, which is Introduction to Manufacturing Processes. This class taught students about additive manufacturing, machining, forging, casting, injection molding, and metal work.

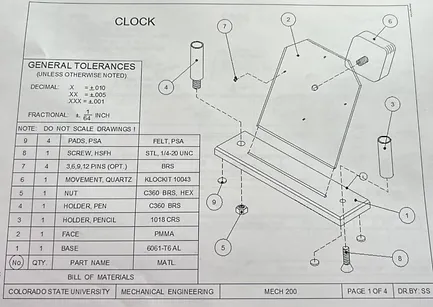

The drawing on the left is the exploded assembly view of the final part. This part was designed by Dr. Steven "Doc" Schaefer.

Process Summary

This particular project utilized nearly every type of machining process. We used:

- Manual Lathes to turn and drill into the pen & pencil holders, as well as the nut shown on the bottom.

- Manual Vertical Mill to cut the aluminum block into the tolerable dimensions, and to add a slot on the bottom of the base.

- CNC Mill to apply the writing on the base.

- Creative freedom was also given for finishing, so I chose to use:

- Sanding by hand, then laquer both the pen & pencil holders.

- Sandblasted the base to give it a clean look while also having texture.

- Beadblasted the acrylic face before adding on the clock hands and battery.

- A hammer and letter stamps to insert our initials into the slot on the bottom.

Finally...

The metal clock took around half the semester, and I spent around 20 hours total in the EMEC. It was a super fun project, and there were a few times I had to restart the pencil holder because I would drill past tolerance into the steel piece or I would crack the acrylic when cutting it.

It was quite a learning curve but it felt amazing to finish the clock successfully. Right now it sits on my mom's desk and she loves it!